What is Computer-Aided Design | Biddeston Engineering

5, September 2024

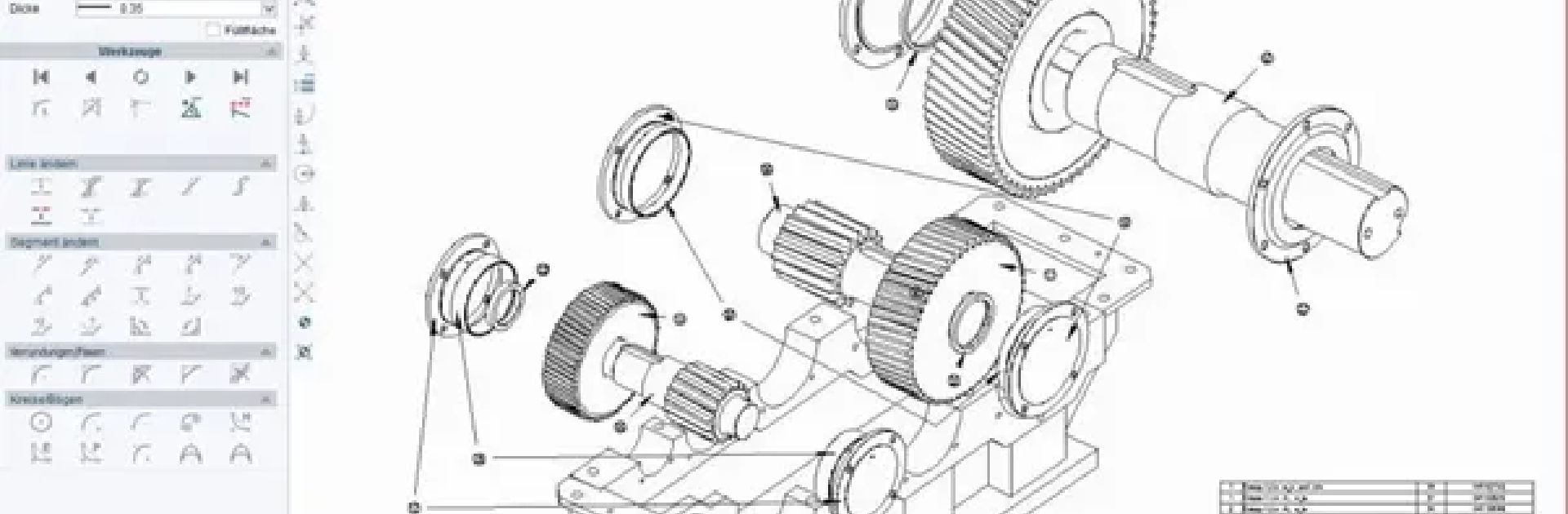

Computer-Aided Design (CAD) software for engineering is a type of software that allows engineers and designers to create, modify, analyze, and optimize digital models and prototypes of products, structures, or systems. We employ CAD software ourselves at Biddeston Engineering, as it provides a wide range of tools and features to aid in the design process, enabling engineers to visualize and simulate their ideas before physical production.

Engineers use computer-aided design software to support their design and engineering processes. Here are some key ways in which engineers utilize CAD software:

Conceptual Design

CAD software enables engineers to create and visualize initial design concepts. They can quickly sketch ideas, explore different configurations, and make modifications easily. This helps engineers evaluate the feasibility of designs, identify potential issues, and refine concepts before moving forward.

Detailed Design and Modeling

CAD software allows engineers to create detailed 2D and 3D models of their designs. They can precisely define dimensions, tolerances, and material properties, ensuring accurate representation of the final product or structure. Engineers can create assemblies, simulate motion, and analyze interferences to optimize the design.

Simulation and Analysis

CAD software offers simulation and analysis tools that help engineers assess the performance and behavior of their designs. They can simulate forces, stresses, heat transfer, fluid flow, and other parameters to evaluate the structural integrity, thermal characteristics, or fluid dynamics of the design. This allows engineers to identify potential weaknesses, optimize designs, and verify performance before physical prototyping or production.

Documentation and Drafting

CAD software allows engineers to generate detailed drawings, technical documentation, and manufacturing specifications. They can create engineering drawings with precise dimensions, annotations, and symbols necessary for manufacturing. CAD software automates the drafting process, reducing errors and saving time compared to manual drafting methods.

Collaboration and Communication

CAD software facilitates collaboration among engineering teams and stakeholders. Multiple engineers can work on the same project simultaneously, making design modifications, adding annotations, or providing feedback. Engineers can also share 3D models or design files with clients, suppliers, or manufacturing partners, enabling effective communication and reducing misunderstandings.

Prototyping and Manufacturing

CAD software integrates with computer-aided manufacturing (CAM) systems, enabling engineers to generate toolpaths and instructions for automated machining processes. They can export designs to CNC machines or 3D printers, transforming digital models into physical prototypes or production parts with high precision.

Design Optimization and Iteration

CAD software allows engineers to iterate and optimize designs quickly. They can explore alternative design configurations, evaluate different materials, or modify parameters to improve performance, efficiency, or aesthetics. CAD software’s parametric modeling capabilities enable engineers to update designs and adapt to changing requirements with ease.

Overall, CAD software empowers engineers to enhance their design capabilities, streamline workflows, improve accuracy, and reduce development time and costs. It plays a crucial role in the design, analysis, documentation, and manufacturing processes across various engineering disciplines.

Contact Biddeston Engineering here today for the best line boring and machining near you.

0400 395 548 Get a Quote